Jet chambers, recovery systems, and dust collectors — standard or fully designed — for your unique application requirements.

Surface preparation of railway cars, trailers, heavy equipment frames, and welded steel structures is critical to your business. Your team may be involved in removing burrs and cleaning half-ton castings and other large metal structures. You could perform abrasive blasting outdoors, but then you would have to deal with inclement weather, dust control regulations, and the costs of manually cleaning up abrasives without reusing them. The solution is abrasive blasting inside a Clemco blast room, equipped with a dust collector and abrasive recovery systems that create a comprehensive, closed-loop solution for abrasive blasting, eliminating the issues of outdoor abrasive cleaning. Ensure safety inspector satisfaction, increase productivity, and perform blasting more economically and efficiently with clean, reclaimed abrasives, quickly recouping your capital investment with Clemco.

Sandblasting chambers

Abrasive blasting can be dirty, exhausting, and dangerous. But well-designed blast cabinets mitigate these issues. Clemco blast cabinets are made from galvanized steel for durability and safety, as well as from bolt-together panels without welding for quick and sturdy assembly. Enhance productivity and ensure safety with a Clemco blast cabinet that meets your tasks, layout, and budget requirements. Three types of products are available:

- Pre-assembled – Delivered to your site ready for installation. These compact sandblasting cabinets take up little space and require only air and electricity to start working.

- Pre-engineered – Available in various sizes and configurations. Pre-engineered blast cabinets provide flexibility for different layouts and short delivery times. They are delivered to your site in disassembled form.

- Fully designed – Custom-designed sandblasting chambers, engineered with your unique requirements and processes in mind, are manufactured to your specifications and delivered in a disassembled state.

Abrasive recovery systems

Recycling thousands of kilograms of abrasive can become one of your largest expenses. And if you do not properly recover the abrasive—separating debris, dust, and fine broken abrasive—you will face downtime for maintenance and reduced productivity. The solution is Clemco's mechanical and pneumatic abrasive recovery systems. Reduce costs, increase throughput, and stay on schedule with fewer reworks using your Clemco abrasive recovery system:

Mechanical – For steel shot, steel grit, and other heavy and/or coarse abrasives

Clemco produces four high-performance mechanical recovery systems:

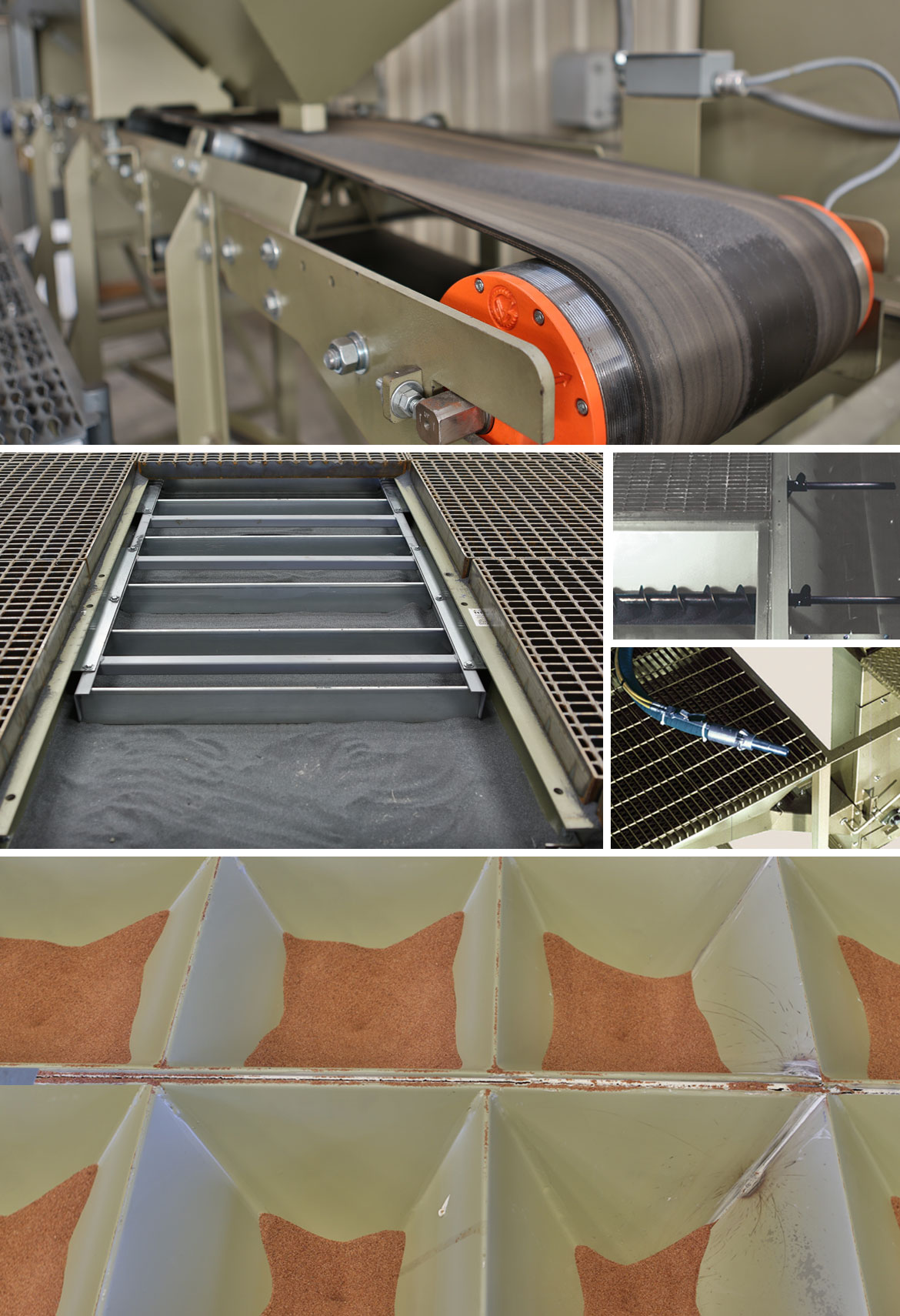

- Belt conveyor – Belt conveyor systems are low-wear recovery systems with passive transfer that can be configured as partial or full-floor systems according to your space, application, and recovery requirements.

- Screw conveyor for recovery – Screw conveyors are a time-tested, economical, and reliable system for recovering abrasives. They can be configured as partial or full-floor systems according to your application and space size requirements.

- Collection hopper – Designed for small sandblasting chambers or abrasive blasting operations with lower volumes, where large capital investments are not required. An above-ground hopper measuring 0.6 m x 0.6 m and a buried hopper measuring 0.9 m x 0.9 m are available.

- Flat-Trak – Flat-Trak recovery floors can be installed in a pit or above ground. Above-ground installation is a practical option when rental conditions, high groundwater levels, or other obstacles to foundation reconstruction prevent excavation work.

Pneumatic recovery system – For glass grit, plastic abrasive, aluminum oxide, and other abrasives of medium and low density

- M-section – Pneumatic recovery systems of the M-section type are designed for the recovery of light abrasives and provide great flexibility for precise abrasive separation adjustment. They can be quickly installed in a pit or on the surface of a foundation.

Clemco recovery system with a belt conveyor

Dust collection systems

Effective dust collection, removing dust from inside blast cabinets and from abrasives, is crucial for optimal visibility, protecting operators from respiratory hazards, and efficient blasting. Clemco dust collection systems are designed for high performance, continuous use, low operating costs, and proper airflow. They help ensure high visibility, clean abrasives, and compliance with regulations so that operators remain productive and safe.