Pipes connect our world. Their applications are manifold: as transport piping in the energy sector, in the industrial sector, or as construction elements. Modern coatings protect pipes sustainably against corrosion, but exert high demands on the preparation of the substrate.

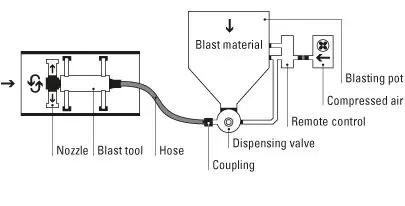

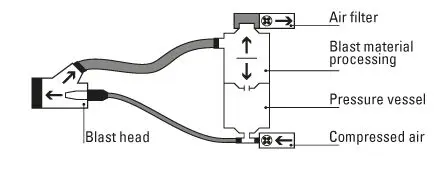

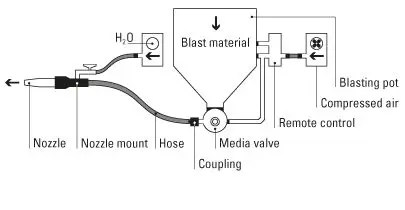

Clemco internal pipe blasting equipment quickly, effectively and reliably removes corrosion, dust and other residue from inaccessible areas inside piping. The operation is simple: a blast hose is fitted with a pipe tool, and the tool is withdrawn from one end of the pipe to the other. Clemco‘s proprietary blast technology applies an even, 360° blasting stream to the inner wall, leaving a consistent blast pattern ready for any coating.

Selecting the proper pipe tool requires sizing the pipe accurately. Smaller inner pipe diameters up to 300 mm are best treated with a Holloblast or Holloblast jr tool, which utilize a deflection tip to create the 360° blast pattern. For pipes with inner dimensions greater than 304 mm, Clemco recommends a Spinblast tool, which uses a rotating blast head to deliver a high-impact, consistent blast finish. Clemco pipe tools can be used on pipe interiors up to 1500 mm in diameter.

The rotating blast head is actuated by either a compressed air inlet or a separate air motor. When blasting larger diameter pipes, or blasting a large volume of pipe, Clemco recommends using an air motor powered pipe tool, which delivers the perfect balance between reliable precision, durability and high-volume blasting.