Industrial systems

Controlled environments for premium blasting

Custom-designed blast rooms are the optimal solution for large workpieces. Clemco staff methodically works with each and every customer to determine their exact blast room equipment requirements. Using this data, Clemco engineers design a blast room tailored to every specific of the job, taking into account each consideration of safety, efficiency and performance. Clemco quality blast rooms set the industry standard worldwide, and every detail reflects this commitment.

Controlled blast environments – for optimal production

«Clemco produces customized blast room equipment that combines all technical, safety and efficiency factors with high productivity, meeting any challenge in the blast industry»

For decades, Clemco has been designing and planning both mobile and stationary blast facilities for nearly every blast application worldwide. Our staff analyzes a customer‘s blast work process, local safety and environmental requirements and productivity needs, and incorporates all of the above into the perfect solution for the best price. Be it upgrading and improving an existing stationary or mobile blast system or designing one from scratch, Clemco will deliver a state of the art system tailored to any need.

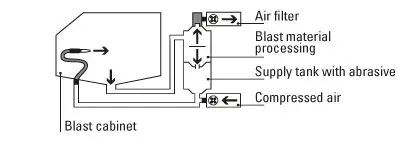

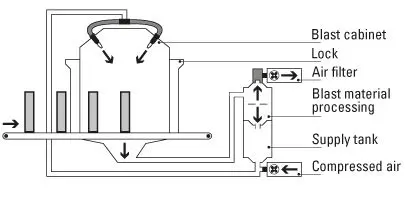

We size and design our blast room components to correspond directly with the parameters of workpiece size, floor space, blast application, abrasive media, process integration and safety. Customized parts handling, automated blast options, ergonomic work stations and specialized media recycling are all available and can be built to suit any specific of the blast process. Dust collectors for combined paint and blasting, metallization, dehumidification, filtration and all other air process options are also available and can be incorporated however necessary to provide the cleanest blast facility in the market.