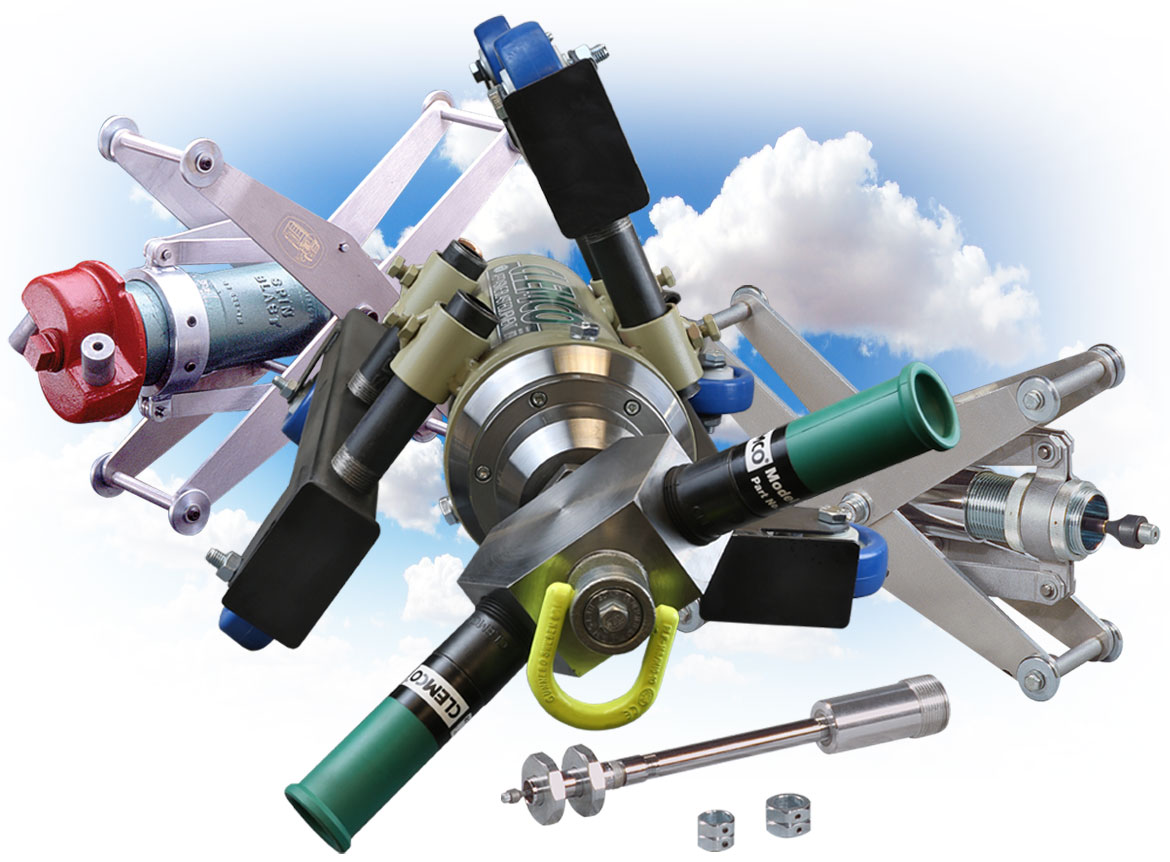

Abrasive blasting equipment

The sandblasting equipment you need depends on the work being performed (or types of work):

If your tasks range from spot processing to complex ones, from coal slag to crushed glass and everything in between, then a machine with a capacity of 14 to 170 liters that can be transported in a pickup truck will provide the necessary flexibility and mobility.

Our two-chamber units with a capacity of 226 liters or units with a capacity of 283 or 566 liters are ideal for high-performance tasks that require long intervals of continuous jet processing.

For even larger jobs with multiple operators and nearly continuous blasting, more powerful equipment is required, which is why Clemco manufactures large-scale units with capacities of 1700, 3400, and 4530 liters.

Reduce downtime and ensure the continuity of your operations. Continuously replenish your inventory of accessories and spare parts, such as nozzles, hoses, couplings, metering valves, and much more.

Equipment for hydro-abrasive cleaning

Water jet abrasive cleaning has advantages for certain applications:

-

Dust suppression: When the priority is dust suppression to ensure environmental safety and compliance with regulatory requirements. It is especially useful if you are conducting abrasive cleaning in enclosed, urban, or residential areas.

- Reduction of dust emission = increased visibility for the operator and reduced cleaning time = increased productivity.

- Excellent surface cleanliness: Waterjet cleaning washes away the abrasive from the treated surface, allowing for the application of a coating on a clean surface without the risk of delamination caused by contaminants.

Explore our complete range of portable systems for waterjet abrasive cleaning: all-in-one universal units, conversion kits for dry abrasive cleaning machines, and handheld tools for spot treatment. All of them can also perform dry abrasive cleaning, rinsing, and air drying of surfaces. Thus, with one piece of equipment, you can carry out more types of work.

Tools for Internal Pipe Cleaning

The circular jet processing scheme (360°) ensures uniform coverage and a consistent surface profile inside the pipes.

Pipe Pro XL and Spin-Blast – For large diameter pipes from 203 mm to 1.524 metres in internal diameter.

Hollo-Blast and Hollo-Blast Jr. – For small diameter pipes from 19 mm to 305 mm in internal diameter.

Productivity Improvement – The 360° circular jet processing allows all Clemco pipe tools to perform abrasive cleaning faster than manual cleaning by a single operator, increasing productivity and ensuring higher-quality results.

Time and cost savings – No additional equipment is needed for mechanical or manual pipe rotation, thanks to the circular jet system of these tools, saving both time and money.