Improving stability and timely delivery of products

Your production team is working hard. They understand that productivity, stability, and downtime all affect the next stage of the production line. And you know that decreased productivity due to inefficient processes, unstable quality of part processing, and unplanned downtimes negatively impact profits and your reputation.

Clemco understands this. That is why, when you collaborate with Clemco, you receive a solution for abrasive blasting tailored to your required level of automation. Automation that optimizes surface preparation, which in turn improves the cleanliness of part processing, the quality of the final product, and the timeliness of deliveries.

Optimize your entire production process and achieve a quick return on investment with Clemco's automated sandblasting solution.

At the Clemco Manufacturing Facility, Washington, Missouri

Control Systems

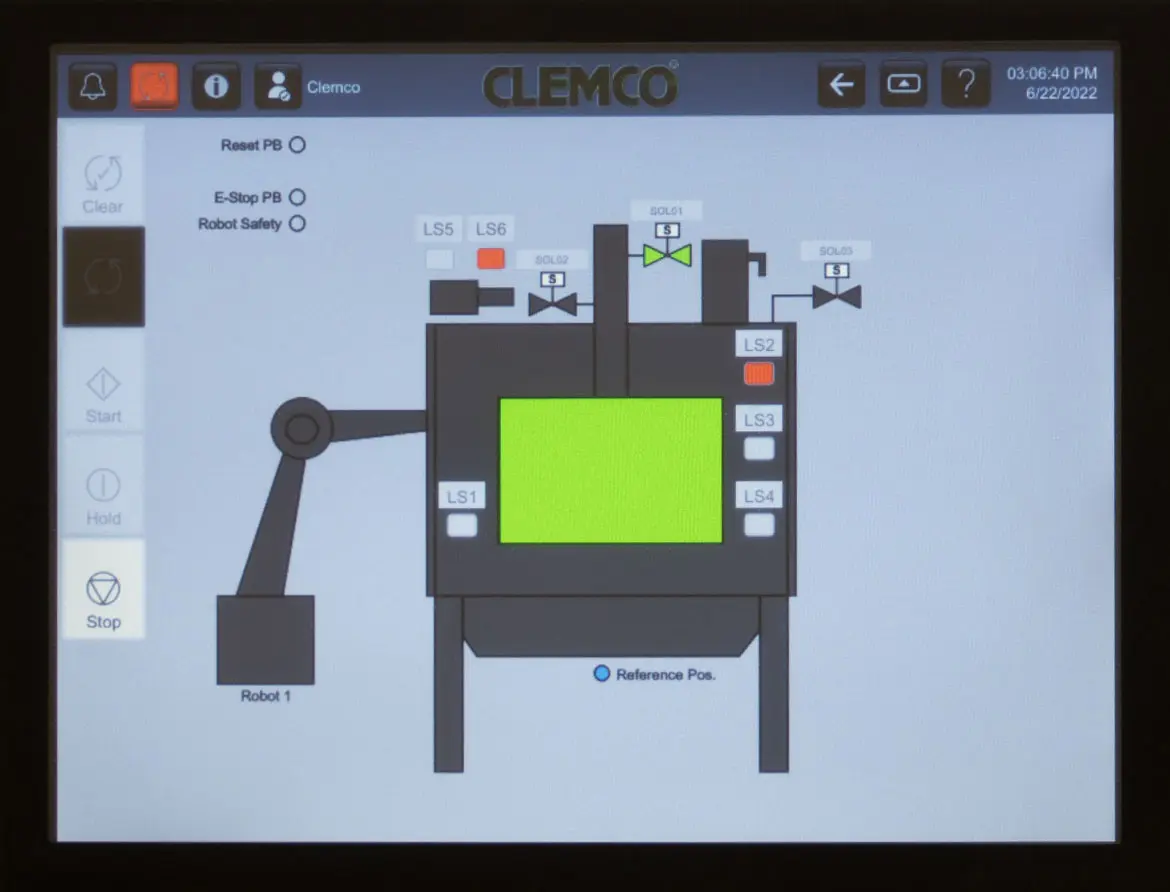

Your clients expect high-quality part processing—and timely delivery. Clemco's automated control systems provide both, promoting ease of use, efficiency, and operator safety. As an OEM partner of Rockwell Automation, Clemco utilizes industrial integrated control systems that offer an intuitive user interface and flexibility, allowing for consistent processing of various parts, increasing the uptime of your sandblasting system, and ensuring higher throughput. Maximize your team's performance and exceed your clients' expectations—with Clemco's automated control systems:

- Touch HMI with realistic graphics

- Automatic air flow control

- Automatic control of dust filters

- Parts barcode scanner

- Recipe system for automatic setting changes

- Frequency-controlled drive (FCD) for precise motor control

- Standardized safe voltage 24 V direct current

- TUV Safety Certification

- System parameters and settings available through HMI

Robotics

You have deadlines. And while your team is working hard, the parts do not wait. Parts with high production volumes or complex finishing requirements can disrupt even the most carefully laid plans. However, adding robotic capabilities to your abrasive blasting system ensures consistent and repeatable results for every part—on time. As an authorized FANUC system integrator, Clemco provides robotic solutions for blasting that your customers need to precisely meet their quality and delivery requirements. Achieve proven returns on your investments—with Clemco's robotic blasting solutions:

- Precise multi-axis movement

- Loading and unloading of parts

- Jet processing and nozzle manipulation

- Integration with the production line

- Motion interface for optimizing cycle time, motion trajectory, lifespan, and energy consumption

- Collision Protection and Detection

Automated solution for jet processing and robotic material processing Automated and robotic solution for jet processing

Connection (Connectivity)

Installation, startup, and troubleshooting should be quick and easy. But when they are not, unplanned downtime occurs, disrupting the entire production process. Clemco Automation Connectivity leverages Industry 4.0 technologies and the Industrial Internet of Things (IIoT) to ensure high throughput, consistency, ease of use, and maximum uptime. Keep your production line moving and inform your operational team with Clemco Automation Connectivity:

- Remote control panels and input/output (I/O) modules with Plug and Play functionality

- Transmitted cycle reports and data logging

- Devices connected via Ethernet for feedback and control

- Connection via cellular modem

Information Management

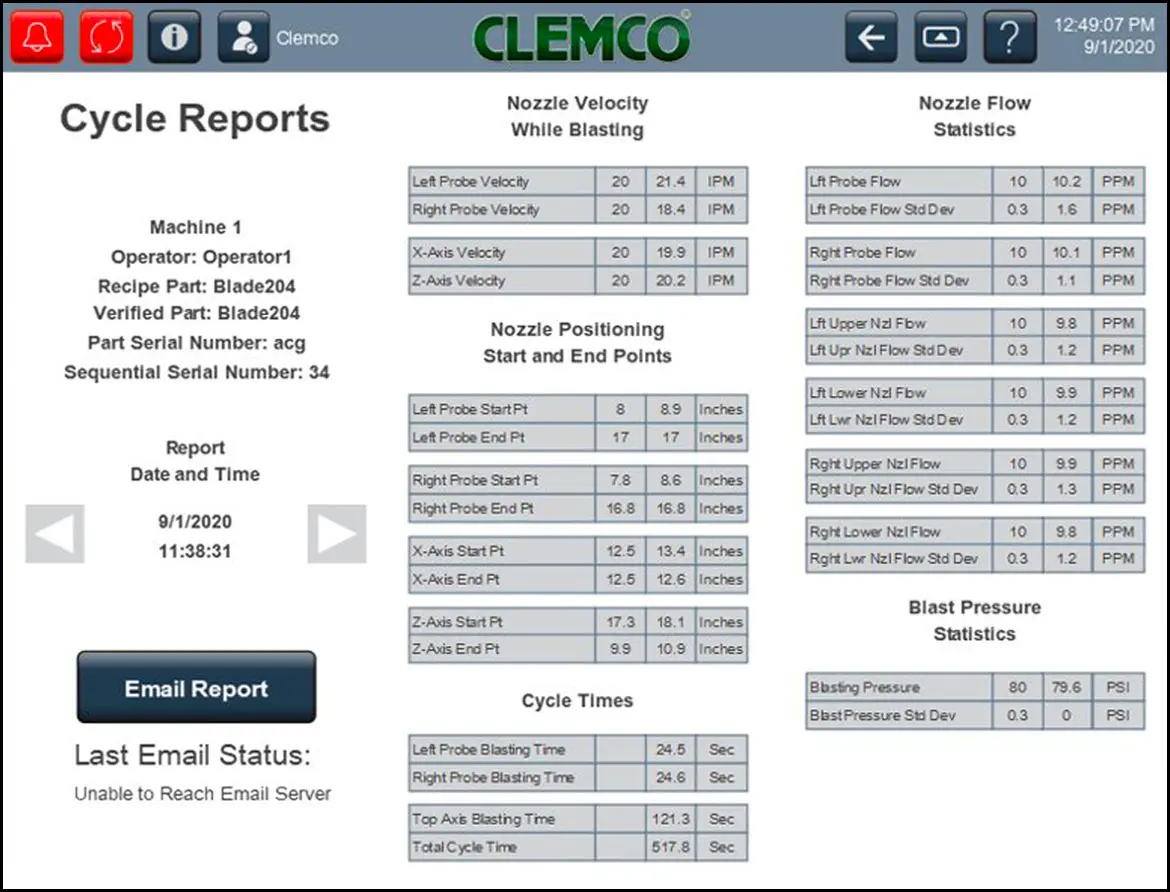

Information is power. The more information you have—and the better it is organized and presented—the better your production line operates. From the performance of individual operators to the overall efficiency of your sandblasting system, you need information presented in a timely, practical format. Clemco's automated information management provides intuitive real-time information so you can proactively plan maintenance, identify trends for improvement, and analyze errors for quick troubleshooting of your sandblasting system. Clemco's automated information management gives you the power of functional knowledge to optimize the surface preparation process:

- Cycle Reports and Performance Statistics

- Fault codes for troubleshooting

- Overview of jet processing parameters

- RFID or operator login

- Sensors for abrasive level, part loading, filter lifespan, system performance, and much more