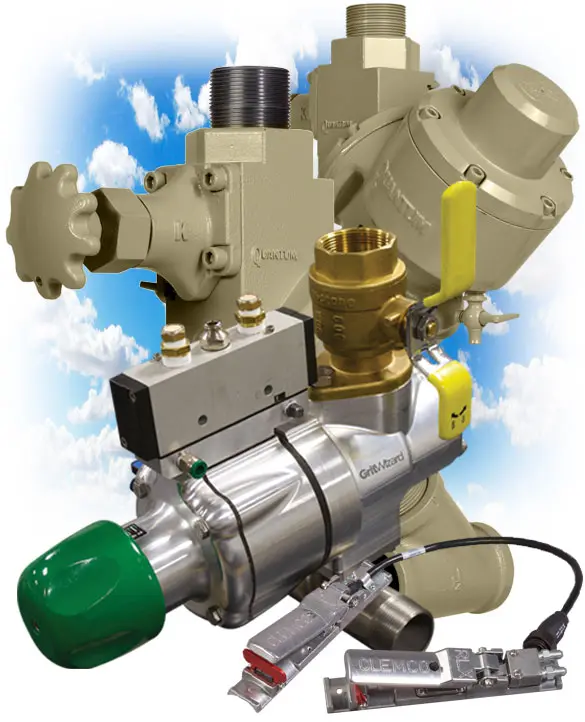

Metering valves for abrasives, remote control panels, sandblasting nozzles, sandblasting hoses, couplings, moisture separators, and more.

This is more than just a sandblasting machine. For safe and productive abrasive blasting, as well as to minimize maintenance costs and unplanned downtime, you need to have the spare parts and accessories that your operators require for their abrasive blasting jobs. The right sandblasting hose, metering valve, sandblasting nozzle, moisture separator, and other accessories designed by the OEM manufacturer to original specifications can make or break your blasting work. So don’t compromise it. Do it with OEM spare parts and accessories from Clemco.

Metering valves for abrasives and remote control systems

The metering valve and remote control are two of the most important components of a sandblasting machine. The metering valve allows operators to precisely adjust the mixture of abrasive and air for maximum performance. The remote control is a mandatory safety accessory required by OSHA that enables operators to safely start and stop their sandblasting machines using controls located at the sandblasting nozzle. Clemco offers a wide range of metering valves for abrasives and remote control systems to ensure you have the equipment necessary to maintain your crew's productivity and stay on schedule without unplanned downtime.

- Pneumatic dosing valves – For pressure relief systems or pressure maintenance systems. Clemco pneumatic dosing valves range from specialized valves for specific types of abrasives and equipment designs to "workhorses" that handle all common abrasives. Three pneumatic valves are equipped with an abrasive shut-off feature, allowing operators to stop the flow of abrasive during blasting operations.

- Manual dosing valves – For pressure relief systems. Five manual valves are offered: from specialized valves for specific types of abrasives and equipment designs to "workhorses" that operate with disposable mineral and slag abrasives, as well as valves that dose all common abrasives.

Remote control systems

- Pneumatic – Used with hoses up to 30 meters long.

- Electric – Used with hoses longer than 30 meters or when working in low temperature conditions.

Nozzles and nozzle holders

This is inevitable. Nozzles wear out. As the nozzle wears and the opening expands, a larger volume of air is required to maintain the necessary air pressure for the application. In addition to increasing air consumption, this inevitable wear reduces the lifespan and performance of the nozzle, as well as increases abrasive consumption. Clemco offers a wide range of nozzles and nozzle holders designed to meet the requirements of various tasks, ensuring that your abrasive blasting system remains profitable and productive.

- Long Venturi type nozzles – For high-performance jet processing with a wide spray pattern.

- Short Venturi type nozzles – For high-performance jet processing in small or confined spaces.

- Direct channel nozzles – When jet processing near the surface, using jet chambers or small jet devices, or when processing objects with complex or detailed surfaces.

- Side angle nozzles – For awkward or extremely confined angles of jet processing, such as inside pipes or in the gaps of metal structures.

- Nozzle holders: nylon and aluminum – Lightweight designs to reduce operator fatigue.

Sandblasting hoses, couplings, and safety cables

The sandblasting hose you need depends on the current task. You may be working on a site where the sandblasting machine is just a few meters from the surfaces being treated, or you may need several lengths of hose on a construction site with vehicle traffic. In addition to the hose itself, you also need the right couplings, gaskets, and safety cables for safe and productive work. Clemco offers a full range of these accessories.

- Sandblasting sleeves – Three types to meet your sandblasting needs:

- Supa – Light and mobile.

- 2-braided – Thicker outer wall and stronger for industrial conditions.

- 4-layered – The thickest outer wall and the most durable. It can withstand even accidental light movement of vehicles without collapsing.

- Couplings – Made from three different materials to meet your sandblasting needs:

- Nylon – Lightweight to reduce operator fatigue.

- Aluminum – Also lightweight, but better suited for vertical jet processing, for example, on construction scaffolding.

- Brass – The strongest.

- Safety cables – The best protection against injuries in case of hose disconnection. Available in three sizes.

Abrasive screens, covers for sandblasting machines, coalescing filters, moisture separators, and Beacon Blast Lights

It's the little things that can give you a performance edge... and prevent downtime. Moisture and debris in your equipment's air line can lead to unnecessary wear and unplanned on-site maintenance, which is why Clemco offers abrasive screens and covers for sandblasting equipment, as well as coalescing filters and moisture separators. We also provide Beacon Blast Lights to improve visibility in dimly lit work areas.

- Abrasive screens – Prevent large debris from entering your sandblasting equipment and causing clogs.

- Sandblasting machine covers – Protect your sandblasting machine from rain, snow, and moisture during unexpected weather changes, preventing abrasive clogs.

- Coalescing filters – Remove water from compressed air to prevent clumping of abrasives and blockages. Two models are available: a flow-through model for a single sandblasting machine and a standalone model for multiple sandblasting machines.

- Moisture separators – A flow device installed before the flow coalescing filter to remove even more moisture.

- Beacon Blast Light – A powerful LED light with a brightness of 860 lumens, designed to attach to the end of a sandblasting hose. It enhances operator performance by improving visibility.