You can’t see coating defects inside a pipe — but your customers will.

Whether you're a pipe manufacturer preparing a new 50 mm internal diameter pipe section for coating, or sending an operator into a 1520 mm diameter manhole for abrasive blasting restoration, manual blasting simply can’t deliver a uniform spray or consistent surface profile throughout the entire area. However, Clemco’s pipe cleaning equipment can. It ensures consistent results, helps you stay on schedule without costly rework, and protects both your reputation and your bottom line.

Tools for Cleaning Large Diameter Pipes: from 203 to 1524 mm

The internal pipe cleaning machines Clemco Pipe Pro XL and Spin-Blast are equipped with two abrasive blasting nozzles mounted on a 360° rotating head.

- Uniform Spray Pattern and Consistent Surface Profile – The two nozzles deliver abrasive at sufficient pressure in a 360° pattern along the inner surfaces of large-diameter pipes. This ensures a uniform spray and consistent surface profile, allowing coatings to adhere reliably without the risk of delamination.

- Productivity Improvement – The dual-nozzle system operates significantly faster than manual blasting by a single operator, leading to increased productivity.

- Time and Cost Savings – Thanks to the 360° rotating heads, there's no longer a need for mechanical or manual pipe rotation, saving both time and money.

- Improved Safety – Manual abrasive blasting of large-diameter pipes is no longer necessary, reducing operator exposure to hazardous dust and minimizing the risk of accidents in tight, confined spaces.

- Four Models Available – Select the model that fits your specific tasks and abrasive material requirements.

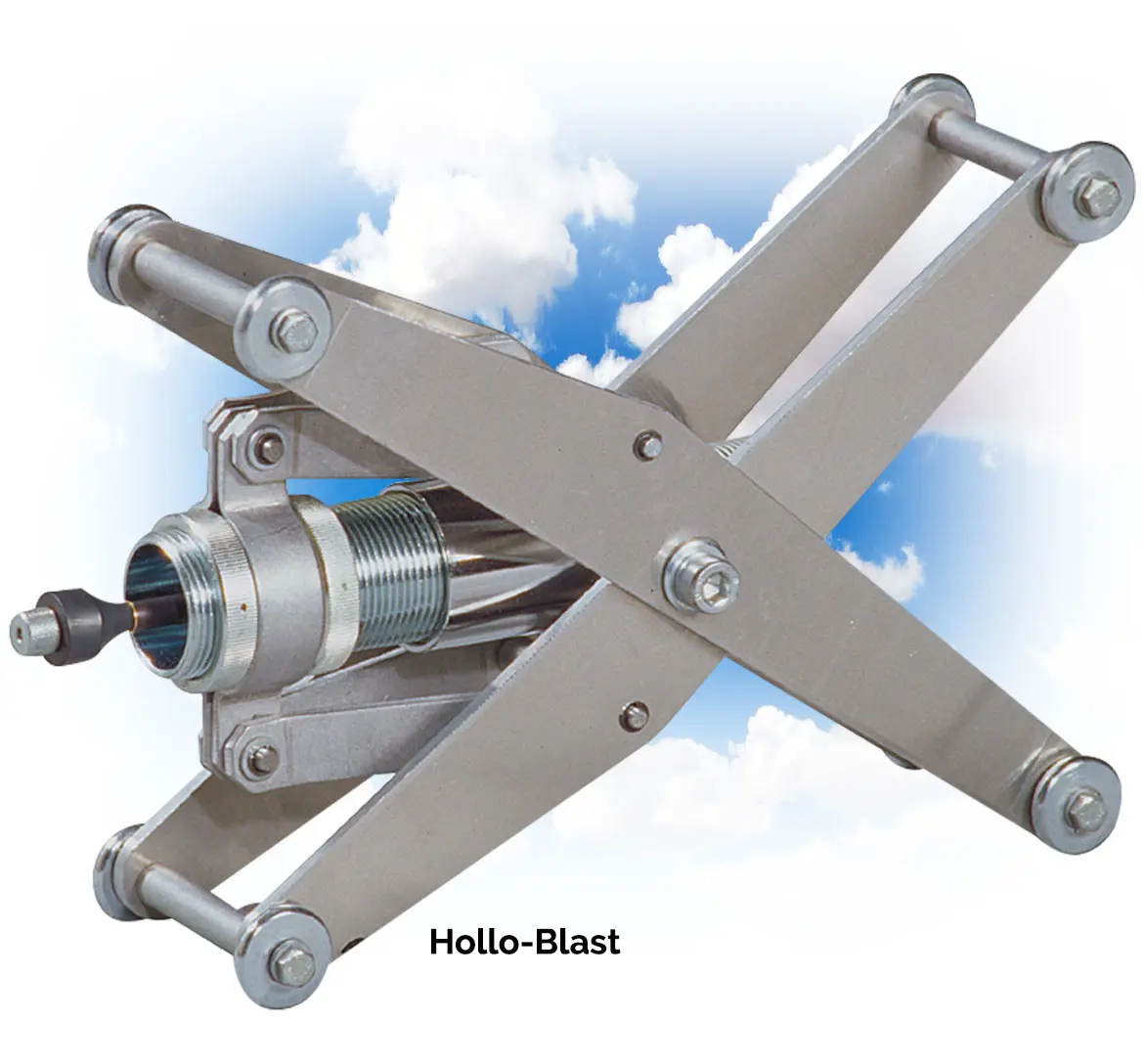

Tools for Cleaning Small Diameter Pipes: from 19 to 305 mm

The Clemco Hollo-Blast and Hollo-Blast Jr. internal pipe cleaning tools are designed for cleaning the inside of small diameter pipes and are equipped with deflector nozzles placed inside the pipes.

- Uniform Jet Stream and Consistent Surface Profile – Compressed air delivers the abrasive to the deflector nozzles. The abrasive is then dispersed in a 360° pattern, creating a uniform jet stream and consistent surface profile. This allows coatings to be applied inside pipes without concerns about delamination.

- Productivity Improvement – The system with deflector nozzles operates faster than manual abrasive blasting, increasing overall job efficiency.

- Time and Cost Savings – There is no need for additional equipment to rotate pipes mechanically or manually, as the 360° nozzles provide complete internal coverage, saving both time and money.

- Eight Models Available – Choose the model that fits your task and abrasive material requirements.